Today we will talk about the construction needs and market planning of a water plant

A Step-by-Step Guide to Setup & Profitability

In our daily lives, the importance of water to the human body is indescribable. It is the main component of the body, accounting for approximately 60% of body weight. Water is not only used to maintain the body’s water balance, but also participates in almost all physiological processes, including digestion, nutrient absorption, cell function, etc. In addition, water can help maintain skin health, regulate body temperature, and more. Therefore, drinking water has an extremely rich market. Since we know that water has extremely rich market planning, how can we invest in construction? This article will tell you!

Firstly, when we are in the drinking water market, we need to have a clear understanding of the sales situation and market share of the existing water plants located 200 kilometers in our region. If there are no more than 5 water plants within a radius of 200 kilometers or their selling prices are relatively high, then I think the feasibility of this matter is relatively high. Of course, the situation varies depending on the region

After completing market research, start planning production equipment. A water line can be calculated based on production capacity, which can be divided into 3000BPH, 6000BPH, 12000BPH, 24000BPH, etc. How to choose a suitable production line for oneself? It can be calculated based on the local population. Cities with a population of less than 1 million can choose production lines below 6000bph, while cities with a population of more than 1 million can choose production lines above 12000bph. At that time, this was not absolute. As a new customer in the drinking water business, my personal suggestion is to consider a 6000BPH or 12000BPH water production line. Because the cost of both is not too high and the production is moderate

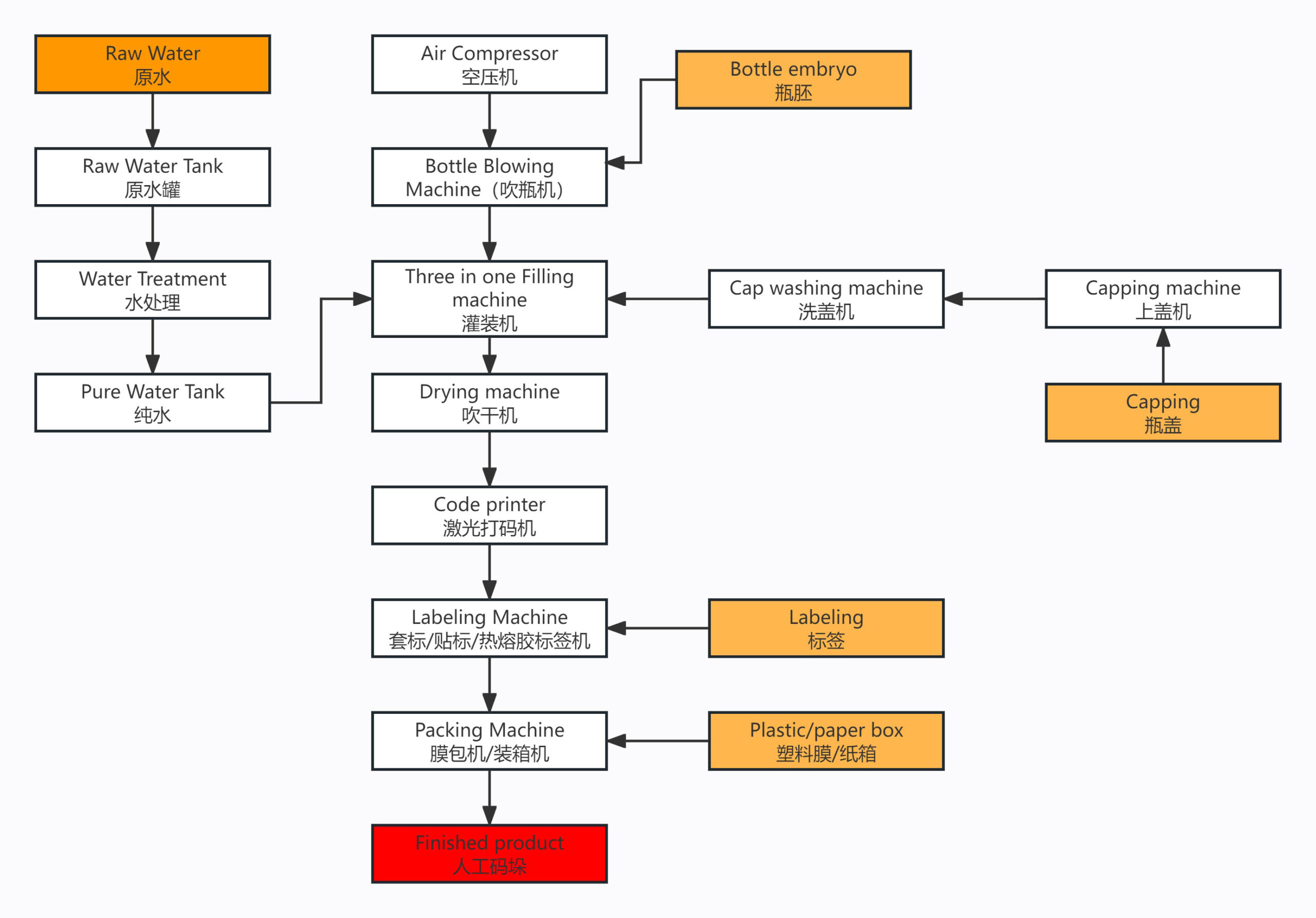

After selecting a suitable production line, we need to purchase equipment. A water production line includes water treatment, bottle blowing machine, filling machine, labeling machine, coding machine, drying machine, packing machine, and other auxiliary equipment. Early procurement of bottle preforms and caps

Attention should be paid in equipment procurement: For the RO membrane used in water treatment, we inform the company to use American membranes. The service life of American RO membranes will be longer than that of other RO membranes. The filling equipment uses a filling valve with two valve openings, resulting in a more accurate liquid level. Simultaneously equipped with lid washing equipment.

The labeling machine is divided into three types of self-adhesive labels, PVC labels, and OPP labels. Among them, OPP tags are the cheapest, equipment prices are moderate, adhesive tags are the most expensive, equipment prices are high, PVC tags are moderate, and equipment prices are cheap. The specific selection depends on the customer’s preference for controlling the cost of bottled water

- After the equipment procurement is completed, consider the water and electricity issues in the factory. Generally, it is recommended that the customer has a three-phase voltage and a total power of 300KW to prepare for the later equipment expansion. If this is not necessary, it is recommended to have 100-200kW.

- After the equipment arrives at the factory, the customer needs to be equipped with several workers and an engineer on site. During installation, the engineer also learns a series of installation and debugging issues.

These four categories of basic steps. Feel free to call if you have any specific questions! Email: huirunmachinery@gmail.com

Phone:+8615262336365