What is a CIP cleaning system

CIP (Clean In Place) cleaning system generally refers to a positioning cleaning system, which means that during the entire cleaning process, the on-site cleaning station equipment forms a closed circulation loop with the production tanks, pipelines and processing equipment, and can be cleaned without disassembling the equipment. CIP cleaning can not only clean equipment, but also control microorganisms, and is widely used in food, beverage and pharmaceutical companies.

The detergent of the CIP cleaning system can be selected according to the nature and degree of contamination of the cleaning object, the material of composition, water quality, the selected cleaning method, cost and safety. Commonly used detergents include acid, alkaline detergents and sterilizing detergents.

CIP cleaning system classification

Common CIP cleaning systems include:

• Integrated CIP cleaning system

• Split CIP cleaning system

• Fully automatic CIP cleaning system

• Semi-automatic CIP cleaning system

Structure of fully automatic CIP cleaning system

• Acid tank: SUS304, volume 500-4000L, etc.

• Alkali tank: SUS304, volume 500-4000L, etc.

• Water tank: SUS304, volume 500-4000L, etc. (capacity can be customized according to customer requirements)

• Process pump, return pump, conversion plate, operating platform, pipeline valve

Purpose of CIP cleaning system

CIP is widely used in food and beverage production enterprises with a high degree of mechanization, such as beverages, dairy products, juice, and alcohol.

Features of CIP cleaning system

CIP cleaning system can ensure a certain cleaning effect and improve product safety

1. The fully automatic CIP cleaning system has low economic operation cost, compact structure, small footprint, easy installation and maintenance, and can effectively clean production equipment such as cylinders, containers and pipelines on site. The entire cleaning process is carried out in closed production equipment, cylinders, containers and pipelines, thereby greatly reducing the chance of secondary pollution.

2. The system can be divided into one to four routes according to production needs. Especially two or more routes, which can not only clean the same or more than two areas in different zones at the same time, but also clean while producing. In this way, the CIP cleaning time is greatly shortened during production.

3. The use of pneumatic diaphragm pumps imported from the United States to pump concentrated acids and alkalis not only improves the integrity rate of the equipment and reduces the maintenance rate of the equipment, but also reduces the operating cost.

4. Especially the fully automatic CIP cleaning system, which can automatically detect, add, discharge, display and adjust the cleaning liquid. It is reliable, highly automated, easy to operate and has good cleaning effect, so it is more in line with the hygiene requirements and production environment requirements of modern large-scale fluid medicine and food processing technology.

5. Automatically switch various process parameters and automatically adjust parameters such as cleaning time, PH, temperature, etc.

6. All operations can be recorded to facilitate GMP certification.

7. The fully automatic CIP cleaning system has single tank, double tank and multi-tank for users to choose from, and is available in mobile and fixed types.

Cleaning agent

Common chemical cleaning agents are: acidic, alkaline, and neutral.

There are several selection principles according to the different dirt

• Oils and fats: surfactants (penetration and emulsification), alkali (dispersion), strong alkali (saponification)

• Sugar carbohydrates: high temperature water dissolution

• Proteins: alkali dissolution, acid dissolution

• Starch carbohydrates: alkali dissolution, acid dissolution, amylase decomposition

In beverage production, CIP cleaning chemical energy is mainly generated by the chemical reagents added to it, which is the most important factor in determining the cleaning effect.

The advantages of acid and alkali detergents are: they can kill all microorganisms; they are better at removing organic matter.Disadvantages: they are highly irritating to the skin; they are poorly washable.

The advantages of sterilizers are: rapid sterilization effect, effective for all microorganisms; generally non-toxic after dilution; not affected by water hardness; forming a film on the surface of the equipment; easy to measure concentration; easy to measure; can remove odor.

The disadvantages are: special smell; certain storage conditions are required; different concentrations have different sterilization effects; easy to freeze at low temperatures; improper use will produce side effects; the sterilization effect will be significantly reduced if mixed with dirt; it is easy to contaminate the environment and leave traces when spilled.

The acid in the acid-base detergent refers to 1%-2% nitric acid solution, and the alkali refers to 1%-3% sodium hydroxide used at 65℃-80℃. The sterilizer is a commonly used chlorine-based sterilizer, such as sodium hypochlorite.

Factors affecting the CIP cleaning effect of beverage filling lines

• Equipment contamination degree and pollutant properties

– Equipment contamination degree, pollutant properties and product production process are important factors that determine the cleaning effect.

– If the CIP conditions are not determined according to its characteristics during cleaning, it is difficult to achieve the ideal effect, and it may even lead to excessive cleaning costs.

• Types of cleaning agents

– The commonly used cleaning agents in the food industry are mainly acids and alkalis, among which sodium hydroxide and nitric acid are the most widely used.

– Alkaline detergents have a good removal effect on dirt with high protein content, but have a certain corrosive effect on food rubber gaskets.

– Acid detergents have a good effect on stubborn dirt that cannot be removed by alkaline detergents, but they are corrosive to metals. Anti-corrosion agents should be added or rinsed with clean water.

– Other detergents such as surfactants and chelating agents are only used when needed. For example, chelating agents can be used to remove metal ions when the hardness of the cleaning water is high.

• Detergent concentration

– Increasing the detergent concentration can appropriately shorten the cleaning time or make up for the lack of cleaning temperature.

– Increasing the detergent concentration will increase the cleaning cost, and the increase in concentration does not necessarily significantly improve the cleaning effect.

– Manufacturers should determine the appropriate detergent concentration based on actual conditions.

• Washing liquid temperature

– Usually, for every 10℃ increase in temperature, the chemical reaction rate will increase by 1.5-2.0 times, the cleaning speed will also increase accordingly, and the cleaning effect will be better.

– The cleaning temperature is generally not less than 60℃.

• Cleaning time

– The cleaning time is affected by factors such as the type of detergent, concentration, cleaning temperature, product characteristics, production pipeline layout and equipment design.

– The cleaning time must be appropriate. If it is too short, it will not effectively remove dirt, and if it is too long, it will waste resources.

CIP cleaning system technical parameters

| Specifications | CIP-0.5 | CIP-1 | CIP-2 | CIP-3 | CIP-4 |

| Alkali tank/L | 500 | 1000 | 2000 | 3000 | 4000 |

| Acid tan/ L | 500 | 1000 | 2000 | 3000 | 4000 |

| Hot water tank/L | 500 | 1000 | 2000 | 3000 | 4000 |

| heating method | Coil, plate, tube heating, steam heating | ||||

| CIP Pump | 10T/H | 10T/H | 10T/H | 10T/H | 10T/H |

| Pump head/m | 24 | 24 | 36 | 36 | 36 |

| Pump power/kw | 2.2 | 2.2 | 5.5 | 5.5 | 7.5 |

Tips: The above CIP cleaning system parameters are standard parameters. If you have special requirements, please let us know!

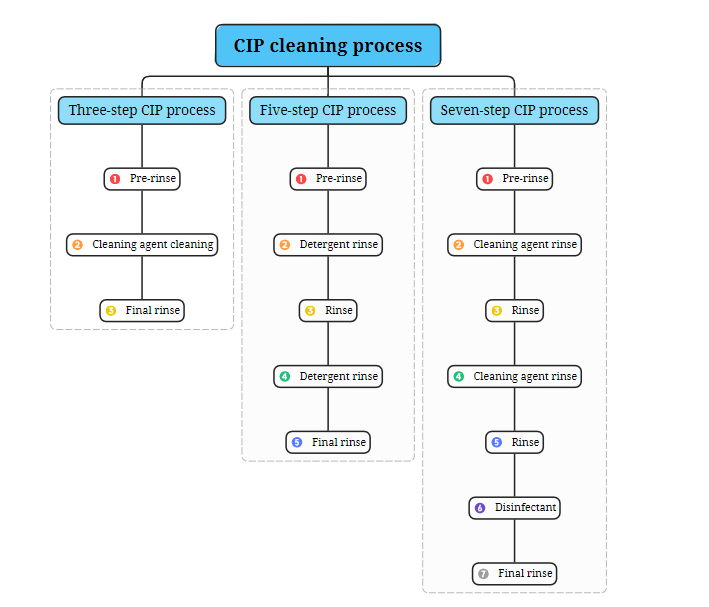

CIP cleaning process

Cleaning flow rate is actually to ensure the flow rate of the cleaning liquid during cleaning, so as to produce a certain mechanical effect, that is, to increase the impact force by increasing the turbulence of the fluid and achieve a certain cleaning effect.

Principles for selecting cleaning process:

• The general process adopts a 3-step cleaning method (water washing-alkali washing-final rinsing)

• The aseptic liquid preparation process adopts a 5-step cleaning method (water washing-alkali washing-water washing-acid washing-final rinsing)

• Water washing uses drinking water or recycled final rinsing water. The water temperature can be adjusted according to different residues. Generally, the water temperature is controlled at 60~80℃.

• Alkali washing uses 2% NAOH solution. The alkaline washing recovered liquid can be recycled under the premise of no cross contamination

• Acid washing uses 2% nitric acid

• Final rinsing uses purified water, and aseptic liquid preparation uses injection water

| Cleaning steps | Container CIP/min | Pipeline CIP/min | Remarks |

| Pre-rinse | 10~15 | 5~10 | – |

| Alkaline solution

circulation cleaning |

20–30 | 10–20 | 1.5%~2.0% sodium hydroxide |

| Rinse | 10~15 | 5~10 | – |

| Acid solution circulation cleaning | 10~20 | 10~20 | 1.0%~1.5% nitric acid |

| Final rinse | >5 | >5 | Subject to the final water quality |

CIP system cleaning schedule

Summary

Through the above overview, the CIP cleaning system provides an efficient, economical and safe cleaning solution for the food and beverage industry, which helps to improve production efficiency and product quality.