A juice filling machine is a liquid filling equipment used for hot filling of organic juice and concentrate, juice with additives, smooth juice or juice with pulp, and tea beverages.

HuiRun’s hot filling machine adopts an innovative PET packaging method and provides an excellent solution for hot filling beverages in PET bottles. It helps to increase product premiumization and revenue generation without compromising packaging performance and operational efficiency. This state-of-the-art juice filling machine is designed to handle high-temperature liquids, ensuring that your beverages remain fresh and retain their nutritional value, making it the first choice for companies in the beverage industry.

Introduction to Juice Filling Machine

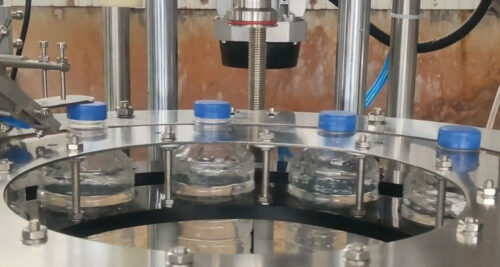

The three-in-one machine integrates rinsing, filling, and capping, and is developed according to the filling process requirements of beverages such as tea and juice. The filling temperature is generally around 82-85 degrees.

The machine is equipped with a complete thermal circulation system and has temperature detection and automatic control functions for the feeding system.

Equipped with an automatic cleaning system, the installation of a cleaning cup can achieve automatic backwashing (our company is currently applying for a patent for this technology).

The machine automatically and continuously cleans the bottle cap sealing gasket during the production process, which can effectively prevent the growth of bacteria.

The transmission star wheel adopts a mechanical arm structure, which is compatible with 350ML-2500ML bottle types, and does not need to replace accessories, making it more convenient to use.

Technical structure features of juice filling machine

a. Bottle rinsing part:

This machine is a rotary bottle rinser, mainly used for rinsing new bottles of beverages, water and other products. Then the bottles are sent to the filling machine for filling of the products.

The bottle washing machine adopts a dual-channel design, which is rinsed with disinfectant and sterile water in turn; the whole process bottle mouth is transported, eliminating the influence of thermal deformation on the bottle body.

The PET bottle enters the equipment from the bottle separation star wheel, and the bottle mouth is clamped by the clamp and the flip mechanism to turn the bottle mouth down. After rinsing with sterile water, it is drained and automatically flipped to the bottle mouth facing up, and transported to the filling machine through the bottle discharge star wheel. The main structure of the equipment is made of stainless steel material, and the part in contact with the rinsing medium and the external protective cover are all open gear transmission.

The new stainless steel clamp has a simple structure and is easy to adjust. It has a small contact area with the bottle mouth, which effectively avoids secondary contamination of the bottle mouth. The rinser is equipped with a water tray to recycle the rinse water. When rinsing bottles, high-pressure cleaning is used, and the cleaning pressure is as high as 1MPa, while the traditional cleaning pressure is less than 0.3MPa.

b. Filling part:

The filling part realizes the filling of materials into the washed bottles sent by the rinser.

The unique new filling valve and reflux circulation system design, the filling cylinder has no return air, which ensures the high cleanliness of the filling material. The filling valve can also reflux in the absence of bottles to maintain the temperature of the valve head; the internal seals of the filling valve are all made of imported silicone rubber or EPDM materials, which have good heat resistance and long service life, meeting the requirements of food hygiene and high-temperature material filling.

The filling valve adopts double closing technology, and the filling accuracy can be controlled within plus or minus 1 mm.

There are no welding points in the filling pipeline to ensure that there are no dead corners in the pipeline.

The filling pipeline is equipped with multiple temperature control points, which can effectively prevent the growth of bacteria caused by the drop in the temperature of the material in the pipeline.

When the temperature of the pipeline material is low, the two-position three-way valve automatically switches, and the material is sterilized again before filling.

The whole machine has a complete CIP cleaning interface.

The double-guide rod bottle lifting structure is adopted to make the bottle lifting and centering stable.

The main drive adopts a gear drive instant opening combined drive, which has high efficiency, low noise, long life, convenient maintenance and sufficient lubrication. The inverter is used to control the speed of the main motor of the machine, and this machine adopts stepless frequency conversion speed regulation.

The bottle guide system has a simple structure and can be quickly and conveniently changed according to the bottle type. The whole machine adopts a bottleneck structure for transportation.

The whole machine is automatically controlled by PLC, and faults are displayed online, such as bottle blocking and missing caps.

The key parts and electrical components of this machine are imported products.

c. Capping part:

The capping part screws the caps sorted by the cap sorter onto the bottles that have been filled with products, and is sent to the subsequent process by the conveyor chain.

The capping machine drives the turntable to rotate through the reducer. Make the cap leave the hopper from the cap outlet under the action of centrifugal force.

There is a positive and negative cap separation device at the exit. When the reverse cap passes, the cap automatically falls into the return pipe, and the reverse cap is automatically blown into the hopper by wind. Only the positive cap can enter the slide smoothly. The amount of caps in the hopper is automatically detected by the photoelectric switch to control the cap conveyor to ensure that the lower cap achieves the effect. When the positive cap enters the slide, it can smoothly enter the cap feeding plate. To prevent accidents, a dial to prevent reverse caps is also configured on the slide to ensure that the caps entering the cap feeding plate are correct. A pair of photoelectric switches are also configured on the slide. When no cap is detected, the main machine is stopped immediately.

In order to effectively remove bad caps without anti-theft rings and residual caps when cleaning the hopper, there is an active outlet directly opposite the hopper outlet to meet this function.

The capping head adopts a constant torque structure, without a twitching feeling, which can reduce damage to the bottle mouth, and has obvious advantages compared with the traditional magnetic torque capping. There is no gnawing, high cap, crooked cap, and curling phenomenon in the capping.

Summary

HuiRun’s juice filling machine provides an excellent solution for the beverage industry with its efficient hot filling design, innovative PET packaging method and intelligent control system. The equipment not only ensures the high quality and freshness of beverages, but also effectively prevents bacterial growth, improves production efficiency and reduces operating costs. HuiRun juice filling machine is an ideal choice for any beverage manufacturer who wants to improve product quality and production efficiency.