HuiRun Laser Coding Machine

Laser Coding Machine is a non-contact printing tool that is widely used in beverage filling machines, juice filling machines, juice filling production lines and other fields to provide product identification and traceability, brand differentiation and security. The device generates sophisticated 1D and 2D barcodes, serial numbers, batch markings and trademark graphics. Its laser marking technology stands out for its versatility, superior quality and durability, offering many significant advantages over other encoding technologies.

Among them, CO2 Laser Coding Machine is an important category of Laser Coding Machine. CO2 Laser Coding Machine is particularly suitable for marking on various organic materials, including paper, PET plastic, glass, wood, cloth and leather, etc. With its high stability, fast printing speed and low maintenance costs, CO2 Laser Coding Machine is very suitable for high-efficiency production environments and marking needs of fixed products.

Compared with traditional coding technology, HuiRun Laser Coding Machine has the following significant advantages:

– High resolution and high speed: Able to meet high-resolution marking requirements in high-speed production lines, such as batch number, date encoding, barcode and logo engraving.

– Accurate and durable: Laser coding uses a strong beam of light to mark specific objects, ensuring the quality, accuracy and durability of the mark, especially suitable for industrial and shipping applications that have high requirements for quality, accuracy and durability.

– Flexibility and versatility: Works with a variety of materials, handles complex part marking, and supports high-quality printing of 1D and 2D barcodes, batch codes, logos, and more.

The HuiRun brand’s Laser Coding Machine is suitable for a variety of industrial marking applications, which can significantly improve product identification and traceability, while increasing the uniqueness and safety of the brand. Whether dealing with high-efficiency production processes or static marking of a single product, HuiRun Laser Coding Machine can provide excellent performance and robust solutions.

The working principle of Laser Coding Machine is as follows

1. Input the content such as English, numbers, graphics, etc. to be printed.

2. The computer marking software converts the content into digital control signals and transmits them to the controller.

3. The controller drives the printing needle to move along the set trajectory in the X-Y two-dimensional plane.

4. The printing needle performs high-frequency micro-impact movement under the action of compressed air, and prints a concave mark composed of dense dot matrix on the surface of the workpiece.

Under computer control, the marking head of the Laser Coding Machine can produce various different pictures and print clear marks on the workpiece through pneumatic methods.

Laser Coding Machine operation steps

1. Turn on the computer and install the software.

2. Adapter air gun.

3. Turn on the printer.

4. Measure the diameter of the printed part.

5. Adjust the height.

6. Open the software, click “Mark”, and “Add Mark”.

7. Click the menu “Burn” and fill in the “Workpiece Diameter”.

8. Check the print needle position, select the layout, and use the “Center” button under the layout menu to set the starting distance of the needle when printing.

9. When ready, turn the upper and lower handles to adjust the needle to a distance of about 0.8-1.0cm from the workpiece.

10. Click to start burning, and press to stop printing if the printing is incorrect.

Advantage

1. Long service life

The laser source of the laser coder has a service life of up to 45,000 hours and requires almost no maintenance.

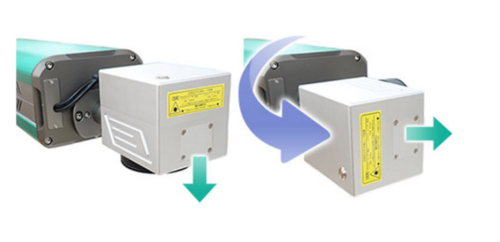

2. Fast installation and line switching

The new external interface system enables fast installation and line switching, reducing downtime.

3. Code quality assurance

The cutting-edge CLARiTY laser control system has embedded advanced software to effectively reduce human operating errors and ensure the accuracy of the code. Equipped with a high-definition scanner, it ensures the uniformity and clarity of the code and maintains the consistent high standard of quality.

4. Convenient and applicable

The sophisticated mechanical structure combined with a variety of customized configurations ensures perfect integration with the beverage filling production line. Provide a variety of beam transmission options and human-machine interfaces to flexibly adapt to various application requirements.

5. Improve production efficiency

A variety of identification window options meet various application requirements and increase identification speed and identification volume. The on-screen diagnostic function tracks the cause of downtime and helps troubleshoot, achieving rapid recovery of the production line.

Strength

• Reduce production costs: reduce consumables and improve production efficiency.

• Obvious anti-counterfeiting effect: effectively prevent product logo counterfeiting.

• Product tracking records: print product batch number, production date and shift for easy tracking.

• Increase product added value: improve product grade and brand awareness.

• High machine stability: with the ability to operate continuously, it can operate around the clock, and the maintenance cycle of the laser component exceeds 20,000 hours. The equipment has a strong ability to adapt to temperature changes and is suitable for production and packaging processes in multiple industries.

• Environmentally friendly and safe: does not produce chemicals that are harmful to the human body and the environment, and meets environmental standards.

• High printing accuracy: can print a large amount of information in a very small space, ensuring the accuracy, controllability and clarity of the printing effect, while being environmentally friendly and non-corrosive, and helping to reduce noise pollution.

conclusion

Laser Coding Machine is popular for its stable performance and convenient operation, and is widely used in industries such as beverage filling machines, juice filling machines, and juice filling production lines. Through correct operation and regular maintenance, the long life and high efficiency of the Laser Coding Machine can be ensured, thereby improving work efficiency and production quality.