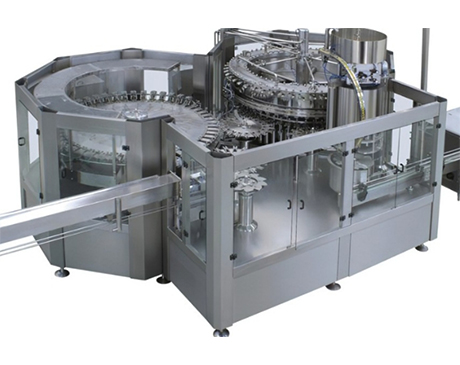

The fully automatic Continuous Inkjet Printer (CIJ Printer) is designed for running barcodes and graphics on production lines, especially for high-volume coding applications that require increased printing and marking capacity. This type of marking system can be integrated with other packaging machines or installed on conveyors to increase production speed and convenience. They can print clear, visible, durable and reliable batch numbers, expiration dates, product models and other information, and are particularly suitable for printing batch numbers and codes on transportation and packaging materials such as cardboard boxes.

Inkjet coding and marking are widely used to print text on packaging, encode directly on parts, or mark products with barcodes and graphics to improve distribution convenience. By installing inkjet encoders on production lines, you can save time and money while improving productivity and quality. These features make it an important part of industries such as beverage filling machines, juice filling machines and juice filling production lines.

Continuous Inkjet Printer Equipment Structure

– Stainless steel housing: All stainless steel housing, in line with IP55 protection standards, can resist dust intrusion, suitable for use in a variety of working environments. The ink system and circuit control system are separated independently to avoid mutual influence.

Advanced ink system design

– Multi-valve pump design: adopts four valve pump designs of ink pump, solvent pump, recovery pump and circulation pump, with constant working pressure, and completes multiple sets of automatic ink processing procedures. Compared with gear pumps, valve pumps have longer life, lower maintenance costs, and lower ink degradation, which can extend the service life of ink and reduce maintenance costs.

– Independent recovery pump: maintains stable and sufficient recovery force, and is equipped with a recovery filter, which is suitable for working environments with large dust. The positive pressure wind function of the nozzle can be realized without external compressed air, preventing external dust or water vapor from entering the ink system through the recovery pipe to contaminate the ink.

– Exhaust gas collection system: an exhaust gas collection pipe is set, and the hose is connected to discharge the exhaust gas to the outside or water to prevent the ink and solvent odor from contaminating the air at the production site.

Advanced startup procedure

– Clean startup: the solvent is sprayed first when the machine is turned on, which avoids the failure and shutdown caused by the ink spraying and the instantaneous deviation when the machine is turned on, and truly achieves clean startup, greatly reducing daily maintenance work.

Advanced nozzle anti-clogging function

– Fully automatic cleaning: independent solvent pump, truly fully automatic nozzle cleaning, each shutdown automatically spray solvent to clean the nozzle and recovery pipeline, to ensure the nozzle and ink pipeline are unobstructed when the next start, improve the stability of equipment operation.

– Triple anti-clogging technology: internationally advanced nozzle triple anti-clogging technology, independent nozzle cleaning program (reverse cleaning and solvent spray cleaning). The nozzle plate can be removed separately and placed in an ultrasonic container for cleaning, completely solving the clogging problem.

Advanced power failure protection system

– UPS power supply system: when the external power is suddenly cut off, the dedicated UPS power supply system can ensure that the equipment continues to operate for a period of time, so that there will be no ink outflow from the nozzle, to protect the nozzle assembly and printed items, and avoid dirt.

Advanced ink viscosity automatic control system

– Automatic adjustment: using advanced ink viscosity control system, and automatic adjustment, not affected by factors such as ambient temperature changes and the length of startup time, so that the Continuous Inkjet Printer always maintains perfect printing quality. Viscosity control adopts the method of detecting the movement time of the float, which is more accurate and reliable than other brands of Continuous Inkjet Printers that detect ink using the dripping time method.

Perfect operation interface

– Large screen LCD display: using pinyin input method and location input method, built-in full set of Chinese character library, direct dot matrix editing function, what you edit is what you spray, what you see is what you get, more convenient operation. Can store multiple pieces of information, with three-line combination and pattern anti-counterfeiting function, flexible row and column selection, more beautiful fonts, more powerful functions.

Unique printing function

– Random code printing function: random code printing function that can be connected to the computer, can receive BMP patterns compiled by the computer, with coding synchronization, photoelectric synchronization, synchronizer synchronization and fixed distance, online one-time detection N times printing function.

Save consumables

– Optimize ink system design: use small ink cylinders, small diameter pipelines, low ink operating pressure and other special ink circuits to greatly reduce the flow and disturbance of the fluid in the pipeline, so that the solvent volatilization amount can be effectively controlled. The consumables consumption is only 10-20% of the traditional air source machine and 60-70% of the gear pump machine, making HuiRun Continuous Inkjet Printer one of the world’s most consumable Continuous Inkjet Printers.

Technical parameters

– Font dot matrix: 5×5, 7×6, 7×8, 8×12, 12×12, 16×16, 24×24

– Printing lines: 1-3 lines adjustable

– Font height: 1.2-15MM adjustable

– Printing speed: 2 meters/second (single line 7×6)

– Printing direction: full-range adjustment

– Font widening: up to 9 times

– Printing content: English, French, German, Russian and more than 20 languages including barcodes, Arabic numerals, graphic logos, etc.

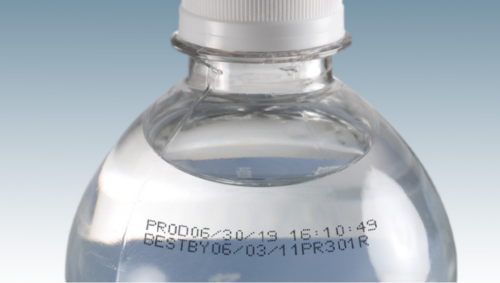

– Printing format: production date, future date or best date, time, shift and automatic counting 2 calculators.

– Computer docking: can be docked with the computer to achieve random code printing

– Receive BMP pattern: can receive BMP pattern compiled by the computer

– Synchronization function: with encoder synchronization photoelectric synchronization, photoelectric synchronization fixed distance, online one-time detection N times printing function

– Power: 30W

– Voltage: 110V (+/-20%), 220V (+/-20%), can be switched automatically

– Power: 50VA, frequency range 45Hz to 65Hz

– Ambient temperature: 5-40℃

– Ambient humidity: 10%-90%RH (no condensation)

– Dimensions: 530X420X290mm

– Weight: 30KG

– Box: stainless steel

Conclusion

HuiRun Continuous Inkjet Printer (CIJ Printer) is widely used in various production lines through its efficient and reliable design, providing great convenience and production efficiency improvement for industries such as bottled water filling machines, juice filling machines and beverage filling production lines.