Semi-automatic blow molding machine is a multi-functional equipment used to produce various plastic bottles and containers.

Working principle: These machines use a combination of manual and automated methods to blow plastic preforms into the desired bottle shape.

Main functions:

•Preform heating and softening.

•Clamping, bottle blowing.

• Bottle ejection and trimming.

Applications: Beverage bottles (water, juice, soda, etc.), personal care bottles (shampoo, lotion, etc.), household chemical containers, pharmaceutical packaging.

Semi-automatic PET bottle blowing machine details

1. Use special electronic control circuit for heating; control one or more lights at the same time with high efficiency; lower power consumption.

2. Use heat transfer and feedback theories when designing the shape and ideas of prefabricated parts.

3. The preform is heated evenly and is not affected by the external environment.

4. Cold air circulation cooling system ensures that the inner and outer surfaces of the bottle are heated equally.

5. The exhaust system designed by CAD can ensure the temperature deviation of the heating furnace is +/-1 degree.

6. The air circuit system consists of two parts: movement and blowing, which can meet the needs of different air pressures and provide stable high pressure for blowing large-capacity bottles of different shapes.

7. The blow molding machine is equipped with a silencer, connecting rod and articulated refueling device.

8. Two operating modes: semi-automatic mode and automatic mode.

9. Small footprint and low investment. It can be operated by one person, simple and safe.

Equipment type

| Features | Manual preform loading | Automatic preform loading |

| Preform loading | Manual feeding | Automatic preform insertion |

| Bottle removal | Manual removal | Manual removal |

| Efficiency | Low | Higher |

| Labor Required | 1-2 Workers | 1 Worker |

| Cost | Very low | Easy |

| Preform handling | Gloves are required when handling hot preforms | Automated preform handling |

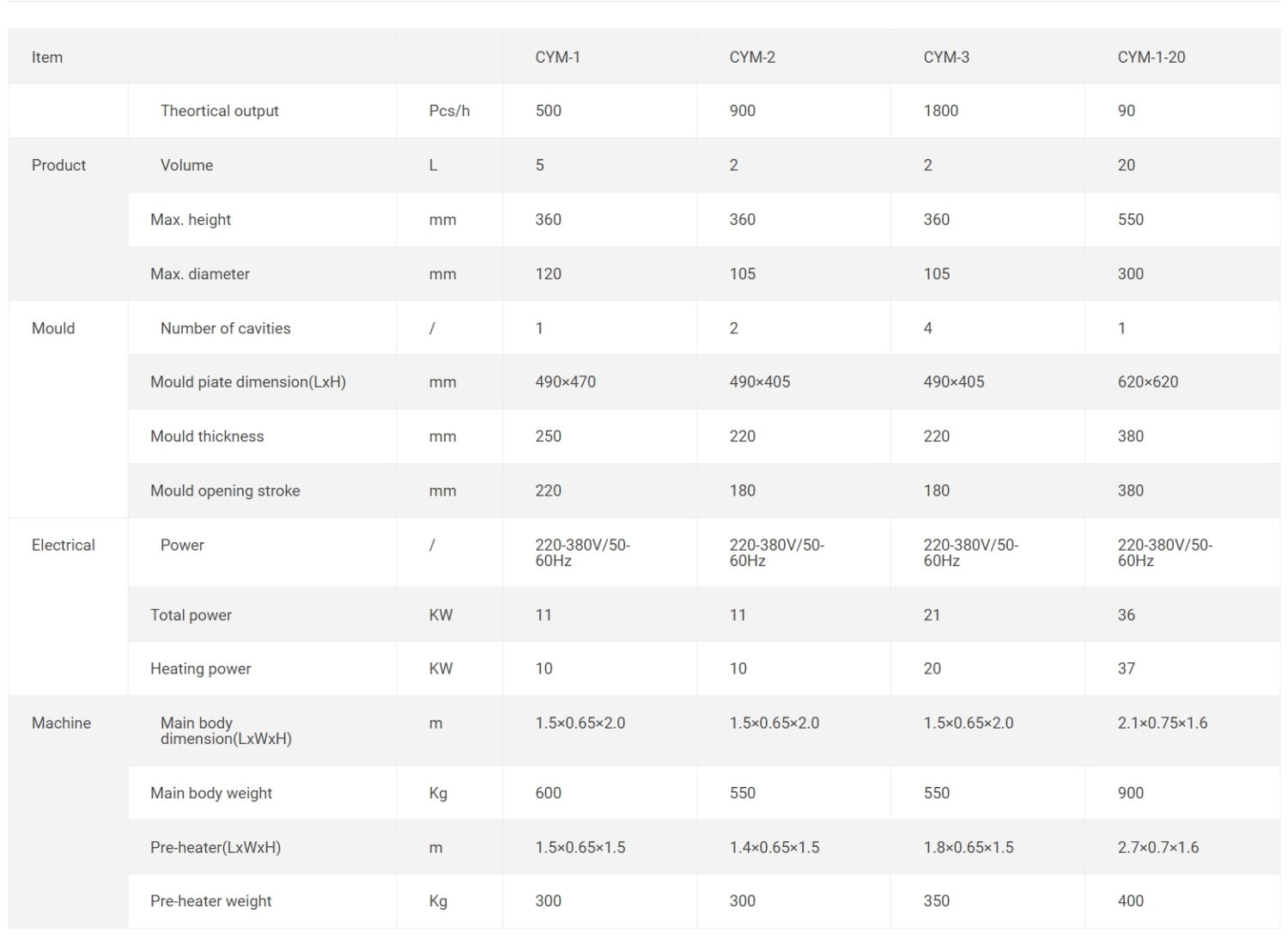

Partial Products Main Technical Parameter

Maintenance and considerations

Regular cleaning and maintenance of molds and machine parts.

Proper temperature and pressure control ensures consistent bottle quality.

Operator training to ensure safe and efficient machine operation.

Consider energy efficiency and environmental impact.