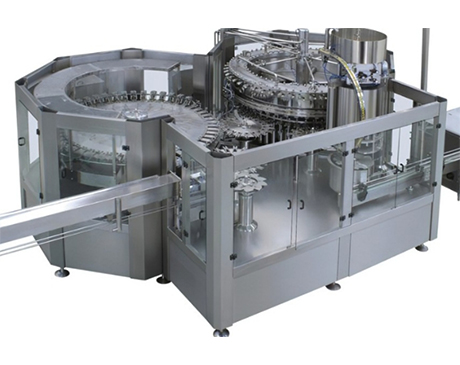

HuiRun is a leading supplier of integrated water flush filling and capping components. Generally, there are three bottle size ranges for different water filling machines:

• 200-2000ml glass or PET bottle

• 2.5L-5L PET bottle

• 5 gallon barrel

Based on 500ml, the production capacity ranges from 4000 BPH to 36,000 BPH.

Our Engineer pays attention to every step of your equipment’s design, manufacturing, and installation. If the layout plan is needed, it is also available after getting your workshop drawing.

Key Features of Automatic Water Filling Machine

This series of equipment is mainly used to produce PET bottled mineral water, pure water, mountain spring water, and other non-carbonated beverages.

• The machine can complete the bottle flushing, filling, and capping in one machine.

• Support various bottle types (PET round bottle, square bottle).

• Capacity 200ml ~ 2000ml, optional with sleeve label or sterilization module.

• Automatic filling system, production capacity of 4000-36,000BPH.

• Food-grade stainless steel with integrated cleaning and sterilization system.

• Supports quick switching of bottle type and capacity to adapt to different scale production needs.

Equipment characteristics

1. The whole machine adopts a bottleneck suspension operation mode design, which makes the bottle stable and reliable under high-speed operation, while greatly reducing variation. More convenient and efficient to change bottle types.

2. Adopting a stainless steel flipping bottle clamp, the clamp is not in contact with the upper part of the bottle mouth thread and is equipped with a nozzle to ensure that the inner wall of the bottle is thoroughly rinsed without dead corners.

3. Using advanced gravity or flow meter filling principles, filling is fast, stable, and accurate.

4. Adopting a constant torque type cap screw to achieve gripping and cap twisting. The tightening torque is infinitely adjustable, and the sealing is tight and reliable without damaging the cover.

5. The whole machine adopts human-machine interface touchscreen buttons, PLC computer control, and is equipped with missing covers and overload protection alarm devices, which can be detected and eliminated promptly. Except for faults, the level of production automation is high.

6. The components in contact with water are all made of high-quality stainless steel, and the main electrical components are made of internationally renowned manufacturers.

7. This machine is equipped with a relatively complete detection system, which can remove the liquid level in the bottle that does not meet the filling requirements and the rotating cap that does not meet the standards. If it exceeds a certain quantity, an alarm will be triggered.

Partial Products Main Technical Parameter

| Model | Washing heads | Filling heads | Capping heads | Production Capacity | Machine power | Weight | Overall dimension (mm) |

|---|---|---|---|---|---|---|---|

| CGF14-12-4 | 14 | 12 | 4 | 4000B/H (500ml) | 3kw | 3200kg | 2500*1880*2300mm |

| CGF18-18-6 | 18 | 18 | 6 | 8000B/H (500ml) | 3kw | 4500kg | 2800*2150*2300mm |

| CGF24-24-8 | 24 | 24 | 8 | 12000B/H (500ml) | 5kw | 6500kg | 3100*2450*2300mm |

| CGF32-32-10 | 32 | 32 | 10 | 15000B/H (500ml) | 6kw | 7500kg | 3680*2800*2500mm |

| CGF50-50-12 | 50 | 50 | 12 | 20000B/H (500ml) | 11kw | 13000kg | 5200*3700*2900mm |

How to choose the right water bottle filling machine for your production needs?

There are several important factors to consider when choosing a bottled water filling machine for your production needs. Here are some key points to help you find the equipment that meets your specific needs.

Determine your line requirements

The first step is to identify the specific requirements of your line, such as the type of liquid to be filled (whether it is pure water, mineral water or other types of beverages), the expected production capacity, and the type of bottles that will be used (including bottle size, shape and material). This will help narrow down the selection and find the machine that fits your specific needs.

Production capacity

Production capacity is a key factor when choosing a filling machine. Different models of bottle filling machines have different outputs, so it is important to choose a machine that can handle your expected production volume.

Entry-level models:

With a capacity of about 1,000 to 3,000 bottles per hour, they are suitable for small and medium-sized businesses. These machines are compact and cost-effective, making them ideal for those new to the industry or businesses with lower production needs.

Mid-range models:

With a capacity of 5,000 to 12,000 bottles per hour, they are suitable for medium to large operations and balance performance, flexibility and cost. These machines typically feature advanced automation, improved rinsing and filling accuracy, and high-speed capping systems.

High-end models:

With capacities ranging from 15,000 to over 36,000 bottles per hour, they are suitable for large production facilities and are equipped with the latest technology to ensure maximum efficiency and accuracy. They feature sophisticated control systems, enhanced durability, and the ability to handle a wide range of bottle sizes and shapes.

Make sure the capacity of the machine you choose matches your business’ current and future needs. Overestimating capacity can lead to unnecessary expenses, while underestimating capacity can lead to production bottlenecks. Anticipate potential future growth to ensure that the machine can continue to function as your business expands. Consulting with a beverage machinery manufacturer or relevant experts can help you determine the model that best meets your specific needs.

Bottle and cap type

The filling machine you choose must accommodate the type of bottles and caps you use. Some machines have greater flexibility and can handle multiple bottle types and sizes, which is very useful for companies that produce multiple products.

Automation and control features

The degree of automation is one of the key factors that determine production efficiency. Bottled water filling machines integrate bottle washing, filling, and capping functions into one device, achieving fully automatic operation, greatly improving production efficiency and consistency. If your production scale is small, you can also consider semi-automatic filling machines, which have relatively low investment costs but can still meet basic needs. User-friendly controls and interfaces simplify operation and reduce employee training requirements.

Durability and maintenance

The material of the filling machine is crucial to the durability and hygiene standards of the equipment. Choose a filling machine made of SUS 304 or SUS 316 stainless steel to ensure that the equipment is corrosion-resistant, easy to clean, and meets food hygiene standards. In addition, the design that is easy to disassemble and clean simplifies maintenance, reduces downtime, and can also help keep the production environment hygienic and the production line running smoothly.

Filling machine supplier

It is crucial to choose a reputable supplier. They can not only provide high-quality equipment, but also provide comprehensive technical support and operation training to ensure that operators are proficient in using the equipment, reduce failure rates, and improve production efficiency. At the same time, timely technical support and maintenance services can ensure the continuity and stability of production.

Budget

Choose a cost-effective filling machine based on your budget. There are equipment ranging from hundreds of thousands to millions, each with its own advantages and disadvantages. In addition to the purchase cost of the equipment, you must also consider the operating and maintenance costs, and choose equipment with low energy consumption and easy maintenance to reduce the cost of long-term use.

Field inspection and trial

Finally, it is recommended to conduct a field inspection and trial. Welcome to Huirun Beverage Machinery’s factory to inspect the equipment and understand the production process and equipment operation. Try the equipment to ensure that the equipment performance meets your production needs and reduce the risk of purchase.

Sum up

By carefully considering these factors, you can choose a bottle filling machine that meets your production needs, ensuring efficiency, reliability and high-quality output.