Video Introduction

Of water production line

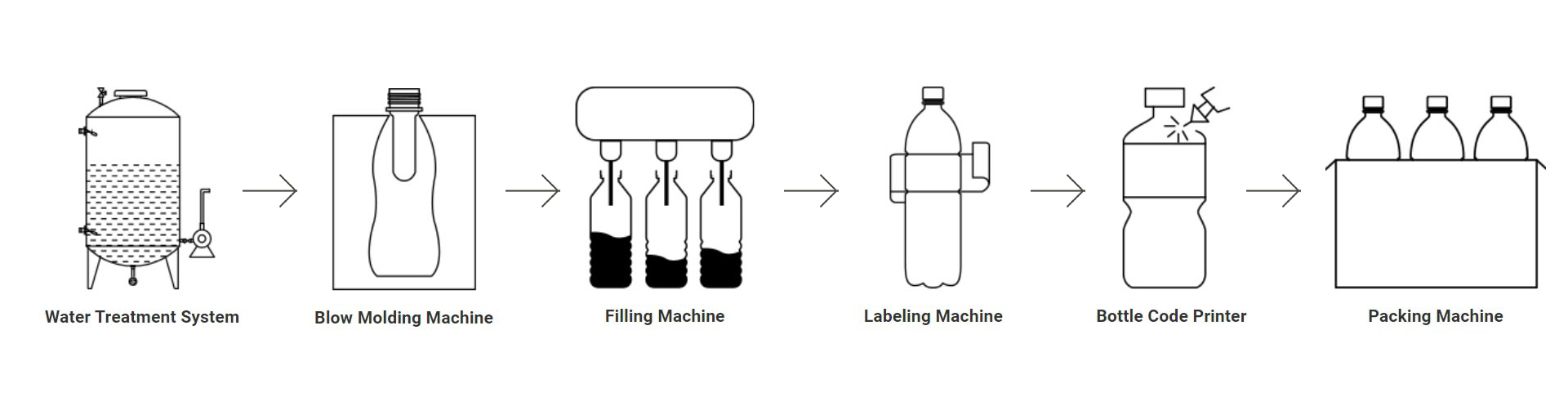

Flow Diagram

HuiRun Machinery offers total solutions of water for you, including 330-1500ml water production line, 3-10L water filling equipment, 3-5 gallon water filling production line.

Each Machine in the Line

Water Treatment System

Water Treatment System

The main function of the water treatment system is to purify and disinfect the raw water, ensure that the bottled water produced meets the high quality standards, and provide consumers with safe and pure drinking water. It is suitable for the treatment of various pure water, mineral water, drinking water, beverage finished water and process water. Water treatment system components:

- Original water tank + original water pump

- Quartz sand filter + activated carbon filter + sodium ion exchanger + precision filter + security filter

- Reverse osmosis (single stage)

- Uv sterilizer

- Finished water tank + pure pump

Blowing Molding Machine

Blowing Molding Machine

The blow molding machine is one of the key pieces of equipment on the bottled water production line, which is used to heat and blow the PET preform (also known as the bottle embryo) into the desired shape of the plastic bottle. It is widely used in bottled water, carbonated beverages, juice, dairy products, cooking oil and other liquid packaging industry, is an important equipment for plastic bottle production. Through the blowing machine, the production line can efficiently and stably produce plastic bottles of various specifications and shapes, and the automated workflow greatly improves the production efficiency and product quality to meet the market demand.

Whether you produce PET water bottles, carbonated beverage bottles, juice bottles, etc., from 200 ml to 20 L bottles, from round to square bottles, we can offer a range of customized solutions to meet your needs.

Filling Machine

Filling Machine

This production line is mainly used for filling drinking water, washing, filling, capping in one, suitable for PET or other plastic bottles. It not only has the characteristics of high efficiency, stable filling and high yield, but also can be used to fill pure water, mineral water, mountain spring water and other non-carbonated liquids. The mechanical gravity filling method ensures accurate liquid level, while having the advantages of high yield and high automation, making it the best in its class.

Huirun Machinery provides 330-1500ml water production line, 3-10L water filling line and 3-5 gallon drum water filling line, suitable for PET bottles, cans and glass bottles filling. Bottled pure water production lines range from 2,000 b/hour to 36,000 b/hour can be achieved to meet a variety of production needs.

Labeling Machine

Labeling Machine

HuiRun Machine offers a full range of automatic labelling machines for glass, plastic and metal containers for the beverage, wine/spirits, daily chemicals, chemicals, pharmaceuticals and packaging industries.

Bottle labeling machines are divided into three categories:

- PVC sleeve labeling machine:Suitable for high-speed production, can accurately and firmly put the label on the bottle body, strong applicability.

- self-adhesive labeling machine:easy to operate, high label accuracy, suitable for containers of various shapes, easy to replace label design, easy to maintain.

- OPP hot melt adhesive labeling machine:low cost, strong label adhesion, can ensure that the label is firm and smooth, suitable for mass production.

The three models have their own advantages, have a high degree of automation, fast speed, stable operation advantages.

Bottle Code Printer

Bottle Code Printer

The bottle coding printer is used to print production date, batch number, bar code and other information on the bottle body. Suitable for bottles of various materials, such as glass, plastic, metal, etc., to ensure that the mark is clear and not easy to wear.

- CO2 Laser Printer:CO2 laser is a kind of gas laser. The CO2 laser has a relatively large power and a relatively high efficiency of electro-optic conversion.Enables accurate, long-lasting marking on high-speed production lines.

- Code Printer:Code printer can print 1-4 lines, and the character size could be adjusted. Printing speed 100m/min, bar code printing 30m/min. easy to maintain, Meet the requirements of high-speed production line. Easy to operate

Both bottle coding printers are efficient, stable, and highly automated to significantly increase the efficiency of the production line.

Packing Machine

Packing Machine

The automatic packaging machine is developed especially for mineral water, beverage, wine, beer, product and so on infusion medicine bottle combination packaging, with stable function, and the packed articles tight and orderly.

- Shrink Film Packing Machine:High efficiency shrink film packaging to ensure the product appearance, suitable for all kinds of bottled beverages.

- Lineal Type PE Film Shrink Wrapper:PE film straight shrink packaging, easy to operate, suitable for bottled drinks of different shapes and sizes.

- High-speed Wrapping Machine:Fast wrapping design, providing stable packaging quality and high-speed production capacity, suitable for large-scale production.

- Carton Opening Packing Sealing Syste:Automated carton unpacking, packaging and sealing solutions ensure safe product transportation and storage efficiency.

Related product