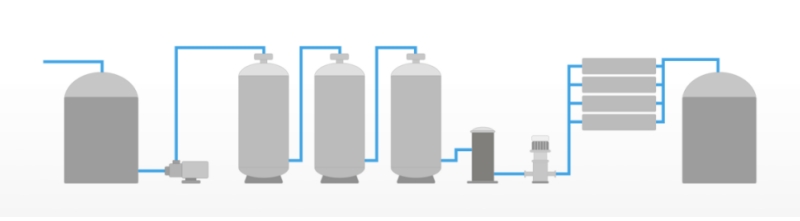

A water treatment system for bottled water is a carefully designed integrated process designed to transform raw water into high quality, safe, hygienic bottled water that meets stringent standards.

Equipment Introduction

Water treatment equipment includes quartz sand filter, activated carbon filter, sodium ion exchanger, hollow fiber, reverse osmosis (RO), ultraviolet sterilizer, precision filter, ozone generator and water tank, etc., with a processing capacity ranging from 0.5 tons/hour to 50 tons/hour.

These equipment can effectively remove turbid organic matter, iron, manganese and their oxides in water, filter out suspended matter, colloids, residual oxygen of microorganisms and some heavy metal ions, reduce the hardness of water, and make various water quality indicators fully meet the national fresh water drinking water standards.

· Customized capacity

The capacity depends entirely on customer needs.

· Durable material

The water treatment device is made of SUS304 material, and the ozone mixing tower tank is made of SUS316 material, which is sturdy and durable.

· Best RO membrane

The RO membrane uses the famous RO membrane produced by Hydecnme Company in the United States. The desalination rate of this RO membrane can reach 99.9%, and it can remove more than 99.9% of ions. It has the characteristics of simple structure, easy operation and high technical level.

Process

Pretreatment stage:

– Raw water enters the sand filter and carbon filter: The raw water first passes through the sand filter to remove large particle impurities, and then passes through the carbon filter to remove organic matter and odor in the water and improve the water quality.

– Water enters the water softener: The pretreated water enters the water softener to reduce the hardness of the water and prevent scaling of subsequent equipment.

Membrane filtration stage:

-Reverse osmosis (RO) membrane filtration: It can effectively remove tiny impurities such as soluble salts, organic matter, and microorganisms in water, which is a key step to improve water purity.

-Ultrafiltration (UF): Further remove colloids, smaller particles and macromolecules in water to improve water purity.

Disinfection and sterilization stage:

-Ultraviolet disinfection: Use ultraviolet rays to destroy the DNA structure of microorganisms to achieve the purpose of sterilization without introducing chemicals.

-Ozone disinfection: It has strong oxidizing properties and can quickly kill microorganisms such as bacteria and viruses, and decompose organic pollutants.

Water quality adjustment stage:

– Adjust pH value: Make the pH value of water reach the appropriate range.

– Mineralization addition (according to product requirements): add minerals that are beneficial to the human body in appropriate amounts.

Storage and transportation stage:

– The treated water will be stored in sterile water tanks and transported through sanitary pipes and pumps to ensure that the water quality is not contaminated before filling.

The entire bottled water treatment system will strictly follow the relevant hygiene standards and quality control requirements during the design and operation process, and continuously monitor and test the water quality to ensure the quality and safety of the final bottled water product.

- RO reverse osmosis for Pure water

- Central control ultrafiltration for mineral water selection

- Choosing nanofiltration for mountain spring water

- Multiple forms of filtering devices can be equipped for alternate use at the same time